March ‘22 - KelpCrofters recycled yurt

One of the main projects here at KelpCrofters over the winter was the construction of a storage shed on the croft. It tends to rain a fair bit here on the west coast of Scotland, so getting things under cover is a good idea. Our existing shed is pretty full (as sheds tend to be), not least with the seeding laboratory. So a new storage space was needed.

In line with our ethics of recycling and trying to reduce budgets as well as waste, we had sourced 10 redundant salmon farm ‘Hamster Wheels’ from across the loch last year, and these had been sitting on the nearby beach for quite a while. These formidable plastic structures are 10 metres across and 2.8 metres high, used to keep bird net suspended above the cages, but hundreds are being retired from use by the salmon companies throughout the Highlands. We borrowed the neighbours tractor to haul one of the hamster wheels from beach to croft, a benefit of living next to the sea, and parked it in the corner of a field. This formed a circular frame onto which we bolted a roof and walls to form a basic weatherproof structure.

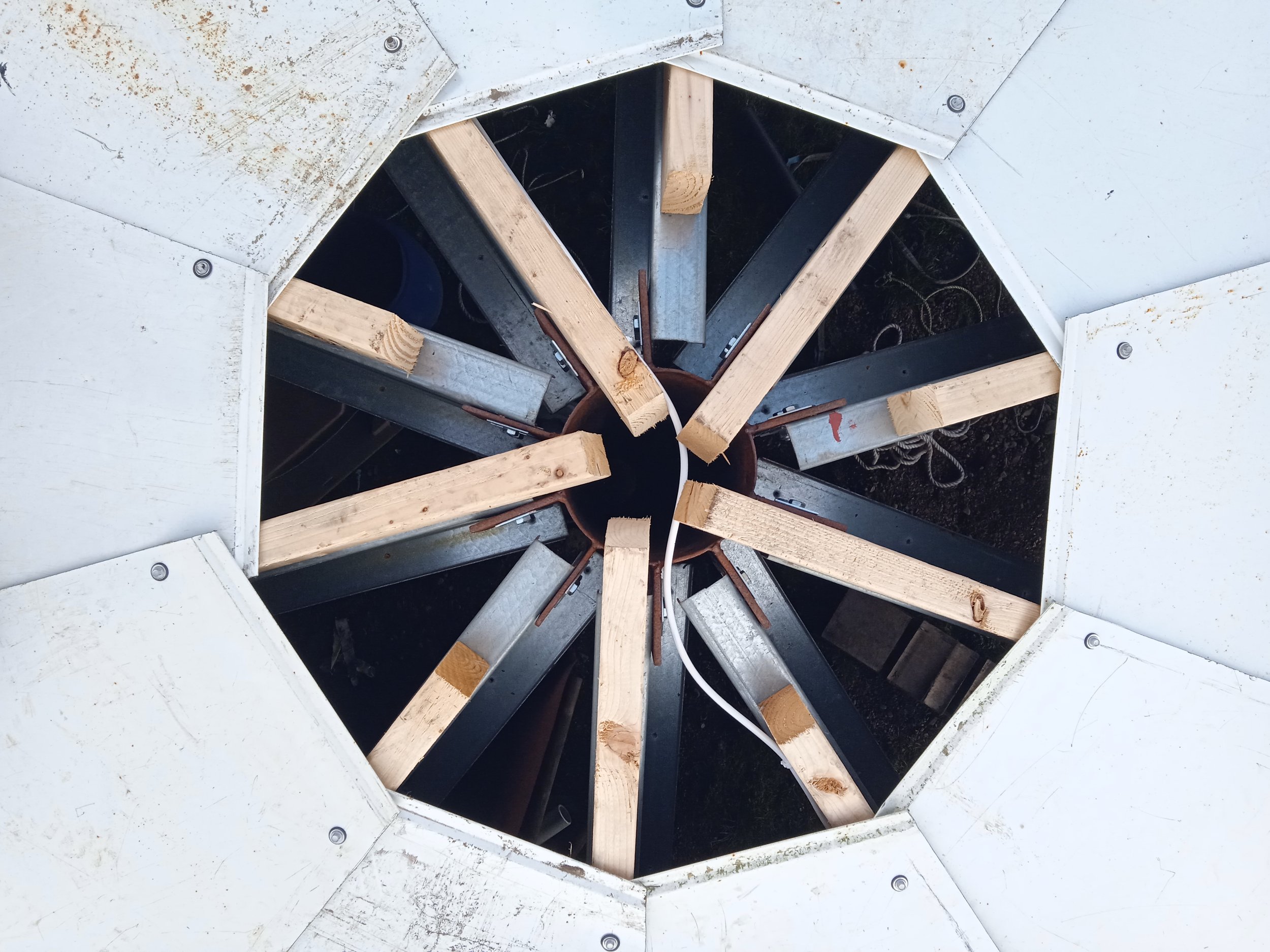

The roof was supported in the centre with an upended big steel pipe (we had picked this up for free). Ten 5 metre steel purlins (free) formed the roof structure onto which we screwed a pizza slice pattern of steel sheeting, created from stripped insulated panels (again, scavenged for free locally). The insulation will be used elsewhere.

The walls were formed from 90mm plastic feed pipe - used in the salmon industry to provide feed to the salmon pens. The feed passing along the pipe gradually wears the pipe out from the inside and it is replaced (all +-3km of it) every fish-cycle (15 months). We scrounged 2km of this last summer, and so set about cutting some of it into lengths then halving these along their length to create an interlocking Spanish roof tile sort of thing. These were painstakingly screwed to the hamster wheel frame to create simple walls.

It was long and cold work through the winter, but satisfyingly cheap, durable and functional. Many hours work, but only a few hundred pounds spent. Much thanks to Alasdair and Laura for the help with the roof. Finally in March the structure was complete, and it quickly began filling up with kit that we were keen to get out of the rain - job done!

Now for the next project, even bigger, watch this space…